Introduction

when a milestone revolution arrives in the era, the scientific and technological advancements of the old era should also keep up with the changes. As robot technology gradually matures, the countdown to its entry into the consumer-grade market is about to begin. The relevant supporting equipment should follow suit and be fully electronicized and standardized. Old-fashioned pots, bowls, pans and other utensils should accelerate their withdrawal from the historical stage. With this concept in mind, I will take the lead as an example and introduce several pieces of equipment ranging from consumer-grade to scientific research-grade.

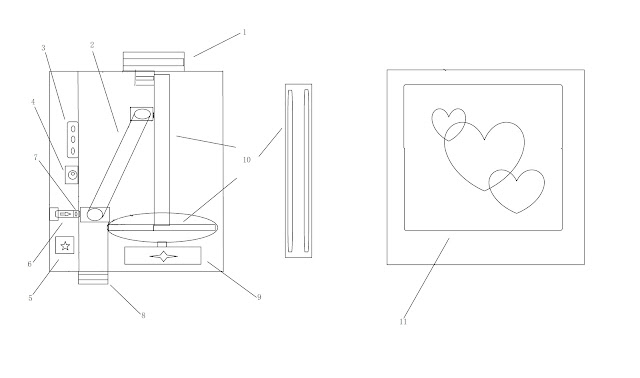

The 3 Generation of Robot Devices for Rapid Refrigeration and Heating of Intelligent Liquid, Solid and Gas Fluids

Function:It can cool and heat fluids. It is particularly suitable for the cooling and liquefaction of vaporized and purified liquids, as well as the precise temperature control during liquid heating. It can accurately control the time and temperature of condensation or heating, and can rotate the heating tube to ensure uniform heating of the fluid.

It can real-time analyze fluid data such as temperature, turbidity (degree of reaction), color, etc. It can also analyze environmental data, checking environmental conditions such as temperature, humidity, and gas content before experiments. During experiments, it can real-time detect and alarm for accidents to avoid the generation of toxic gases, etc.

In addition, it supports customized assembly of external devices and wireless communication and data transmission with third-party devices such as robots to achieve compatibility, coordination, and data recording for various experiments.

Process: There are three liquid inlets (1), respectively corresponding to the heating chamber, the cooling chamber, and the normal temperature chamber. After the fluid enters the rotating quartz cup (3), the computer can control it to rotate at a certain speed to ensure uniform heating of the fluid.

The fluid sensor (11) can observe the changes of the fluid during heating and make data records. The air quality sensor (9) can ensure that the surrounding experimental environment meets the requirements and provide timely alarms for experimental accidents.

Example: It can replace condenser tubes, heaters, etc. The external interface is compatible with various types of containers and can be used in different scenarios. It can detect and record the parameters of the introduced and led-out fluids.

Advantage(s):Water or oil can be injected between the rotating device and the heating ring to achieve more uniform heating and higher temperatures.It can promptly alarm for experimental accidents and accurately record heating data such as the number of rotations and heating time, so as to reproduce the experiment next time.

Multi - stage shunt robot components

Function: In particular, it can uniformly introduce multiple fluids and divert and output them as needed. It can standardize the manufacturing process, reduce openings through centralized processing, and can be intelligently matched with various third - party devices for use.

Process:The rotation of the motor (6) can drive the water outlet pipe (3) to rotate. After rotating by a specified angle, a designated water outlet (4) can be positioned, so that the liquid flowing in from the water inlet (1) flows out directionally.

Example:Used in conjunction with the upper heating device, it can output the liquid to the heating chamber or the cooling chamber.

Advantage(s):Taking the disk as the water outlet, water pipes can be set up 360 degrees. As long as the diameter of the circle is increased, more water outlets can be set up, making it more convenient to manufacture and making up for the defect that there are only three-way water valves on the market.

Solid - fluid Precision Extraction Robot Devices

Function: The fluid can be extracted as required, especially in the extraction of non-Newtonian liquids and solid particles, it has a relatively stable output.

Process: Taking the extraction of non-Newtonian stratified turbid liquid as an example, the rotary homogenizer head 9 can be used to preliminarily and uniformly mix the turbid liquid that has been stationary for a long time. By rotating the double-layer leakage plates 2 in a staggered manner, the lower leakage plate can control the size of the leakage holes to determine the output volume of the fluid for each rotation. By adjusting the rotation speed of the upper closed leakage plate through the motor, the output rate of the fluid can be controlled.

The sensitive electronic scale 4 can be used to control the one-time output volume, which improves the error tolerance rate and avoids the situation of liquid blockage. By reversing the motor 6, the output mode of the fluid can be controlled, such as outputting a specified mass of fluid at one time or continuously outputting a fixed mass of fluid with millisecond-level precision.

The computer 7 can record the data of each operation and synchronously share and save it in the cloud. Multiple extraction devices are provided for a single experiment to sort out and analyze the extraction data of different fluids, which is suitable for joint auditing by multiple researchers to avoid repetitive labor. In cooperation with the robot, it can automatically optimize and retry in case of experimental data errors.

Manual operation can be carried out through the touch display screen 11. The fluid sensor group 3 can analyze the fluid parameters and display them on the monitor, enabling timely monitoring and alarming of the fluid quality.

Example:Compared to spoons and droppers. Replacing time with the number of rotations can greatly improve the stability of the device. The automatic data recording by the computer can save a great deal of time for laboratory technicians. The data is shared synchronously with the robot, enabling automated experiments and intelligent auxiliary optimization of experimental results after inputting formulas and main parameter data.

Advantage(s):Equipped with a grinding rod, it can grind large solids into small particles for extraction and homogenize emulsions before extraction. Weighing is performed before each extraction, which is very useful for subsequent stirring or adding chemical reagents, avoiding inaccurate data caused by unified weighing. It can be directly used in combination with storage devices to prevent interference from substances such as moisture after the object comes into contact with air, which may cause abnormal extraction data. The device is equipped with an intelligent system that can report and analyze the data of each extraction and communicate with other robotic devices. The interior of the cup is precisely manufactured to minimize friction and is equipped with an ultrasonic vibration device to assist the falling of the extracted materials.

Devices of the Intelligent Conveyor Robot for Fluid Pretreatment

Function: Grind and stir the introduced objects, while performing ultrasonic accelerated extraction and activating the liquid. The graphene heating plate can rapidly heat the introduced materials. The full-spectrum lighting module allows for customized loading of experimental light sources as needed, such as ultraviolet, infrared, X-ray, blue light, yellow light, etc. The lighting and visual sensors can real-time monitor changes in reaction phenomena inside the vessel, such as color and turbidity. Non-contact radio frequency sensors can detect the temperature of reactants inside the vessel, etc. Gravity sensors can real-time detect the degree of reaction to determine the ratio of reactant residue to time. The pump can actively output viscous substances, and the computer can synchronize all the above data to the cloud for timely recording and collaborative use with third-party devices.

Process: A customized shunt device can be externally connected through the threaded external interface 1, which allows for the simultaneous introduction of multiple fluids in different ways and conducts stirring at a fixed speed. For example, different shunt ports of a shunt device such as a three-way shunt can be externally connected to a condenser, and a robotic device of an intelligent precision switch grinding funnel can be used to take out solids at a fixed time and in a fixed quantity and to drip liquids. Before that, different substances can also be added to the specified quantity through the gravity sensor 6, and then subsequent operations can be carried out, while the remaining reactants can be monitored in real time. A gas collection bottle can also be externally connected to collect the reaction gas. The full-spectrum emission module can emit ultraviolet rays for liquid sterilization or photochemical reaction research inside the vessel.

Example: It can be used to replace the scenario of combining a three-necked flask, an electronic balance, and a stirrer. The advantage is that it provides the ability to record and process data compared with the combination. Under specific conditions such as slow stirring, ultrasonic accelerated extraction of experimental solids can be performed.

Advantage(s):Lay the foundation for future robots to operate experimental equipment, simplify experimental setups, unify experimental equipment, and improve experimental reproducibility.

Smart Centrifugal Robot Device

Function: The equipment storage device (2) can store test tubes for liquid centrifugation, and can also store surgical tools such as various scalpel tips and customized spray guns, which can be used as a multifunctional surgical hand after being assembled into a mechanical arm.

Process: The telescopic electromagnetic thruster (6) can be used to grab and release the equipment storage device (2). The equipment storage device (2) can align its nozzle (1) with the slide rail (10), allowing external fluid to enter the designated equipment storage device (2) or pushing the equipment storage device (2) out of the nozzle for subsequent use. The differential motor rotates at high speed to centrifuge the fluid in the equipment storage device (2), and then the fluid is led out through the nozzle (8) to enter the next-level equipment for automated subsequent processing.In a disc-shaped configuration, one product can carry multiple equipment storage devices (2), which can store various sub-components. Specific sub-components can be used by rotating the disc, and the sub-components are identified and positioned via built-in high-definition cameras.

Example:It can be used as a centrifugal device in manipulators or automated experiments.

Advantage(s):The product has strong compatibility and can be assembled with sub - components of various functions as needed, achieving multi - purpose use with one machine. It can quickly eject and retract specified sub - components with strong stability. It can also be used as a centrifuge.

Examples of assembling the above devices

Function Introduction of the Intelligent Variable-speed

Incineration Robot

The incineration toilet in the RV solves the problem of defecating and urinating when there is no water. Inspired by this, this multi-purpose rapid incinerator was born to solve the problem that it takes an hour for an incineration barrel to burn a lump of excrement.

The principle is that while the blender blades of the intelligent fluid pretreatment and conveying robot device (2) crush the combustibles, the combustion liquid is added through the solid-liquid precise extraction robot device (10) and stirred along the way, making every cubic millimeter of the non-combustible combustibles become combustible. Then, through non-contact rapid ignition by laser while continuously stirring, the combustible surface area is increased, enabling the combustibles to fully contact with oxygen for combustion, thus greatly accelerating the combustion speed.

Store various types of fuels, such as solid powder, liquid, gas, etc., through the fuel tank (8). Only 10 to 20 grams of gasoline can be selected as the combustion liquid, which can be burned out within 1 to 3 minutes, and the cost is less than 1 yuan. By using the hair dryer (5), sufficient oxygen during combustion can be ensured.

The gravity sensor of the intelligent fluid pretreatment and conveying robot device (2) and mathematical calculations are used to ensure that the combustibles are completely burned. If they are not completely burned, an appropriate amount of fuel can be added again through the solid-liquid precise extraction robot device (10) for continuous combustion. After the combustion is completed, the device is reversed to pour out the incombustibles into the garbage collection device (3).

The combustion exhaust gas is treated through the reverse osmosis device (6) and the aroma device (8).

Commercial uses: Incineration barrels for various items, such as medical waste and chemical waste. Incineration toilets are used in recreational vehicles or in the field of environmental protection.It can be used for baking trays (for short-term use such as grilling meat) and ovens (for long-term use such as barbecuing whole lambs). When the lid is opened, it can also be used as a gas stove (similar to a cooking stove in rural areas).

Advantages: Fast burning speed, high temperature, good safety of the explosion-proof barrel, and wide range of applications.It can be externally connected to a steam generator to generate electricity from the discharged gas. This allows both burning waste and using heat energy for cooking, while also generating electricity from steam. Generating electricity from waste can save daily expenses. It helps the environment and can also provide electricity in outdoor emergency situations.

Pharmaceutical/Nutrient Solution/Beverage Dispenser

Inspired by the making of milk tea, all kinds of liquid preparation are inseparable from processes such as heating, stirring, distilling, and cooling. Dozens of milk teas can be made using more than 10 base materials. Compared with purchasing machine cases for various types of beverages, the preparation method has significant advantages in customization, diversity, cost-effectiveness, and other aspects. Based on this, it can be extended to the preparation of pharmaceutical nutrients for different patients, perfume blending, and even the replication of future AI chemistry-related content. This equipment can provide robots with fast auxiliary solutions and significantly help with data recording and sharing. After unifying the equipment, a data ecosystem can be established, including global beverage preparation recipes, pharmaceutical production, chemical experiment process data, etc. Uploaders can receive rewards, and downloaders can easily replicate expert achievements one-to-one.

Solid - fluid Precision Extraction Robot Devices(1,2,3), 1. Used for storing viscous substances such as syrup, milk tea pearls (objects fall vertically into the pipe, try not to contact the pipe wall as much as possible to prevent loss). 2. Used for storing particulate matter, such as juice powder, coffee powder, tea powder, etc The 3 Generation of Robot Devices for Rapid Refrigeration and Heating of Intelligent Liquid, Solid and Gas Fluids Brew it with warm water. 3. Used for storing liquids such as alcohol, cola, Sprite, etc. The Devices of the Intelligent Conveyor Robot for Fluid Pretreatment (4) can uniformly weigh multiple materials again to ensure no errors, perform composite stirring and ultrasonic accelerated extraction on multiple materials, and further increase the temperature. Finally, use Multi stage shun robot components to control the material output port. First, output the liquid through one side of the dense small hole, and then output the residue through the other side to the waste disposal site for incineration.The freezer (5) provides cups filled with ice cubes and additives such as coconut fruits

Commercial uses: Nutritional soup preparation, beverage mixing, and liquor blending. Used in schools, hospitals, and subway stations. Replaces beverage shop staff.

Advantages:All components are exclusively designed and manufactured. The claim that "latecomers surpass the predecessors" is nonsense; it's nothing more than plagiarism and剽窃 (plagiarism). Without being 'borrowed' by others, I believe my products and components are invincible. All components are experimental-grade equipment. Take the fluid extraction device as an example: it can accurately measure the gram weight of fluid by controlling the number of rotations and using a precision electronic scale. Compared with methods that control time, it completely outperforms in stability when handling complex fluids such as emulsions.

The electronic devices can share data with the robots, which can improve the experimental accuracy, reduce the operation procedures, enhance the work efficiency, realize a fully automated process, and increase the literature reproduction rate.

评论

发表评论